SURFADOL ® 541 Surfactant

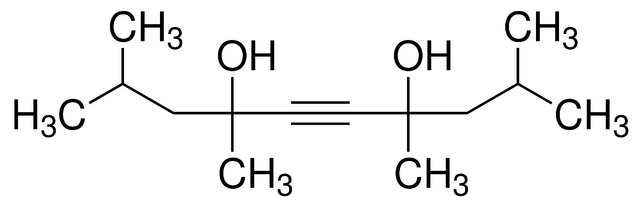

SURFADOL® 541, CAS 126-86-3, alternative to Surfynol 104

Nonionic Dynamic Wetting Agent and Molecular Defoamer

SURFADOL® 541 Surfactant

Surfadol 541 surfactant has a unique Gemini structure, which brings a unique combination of performance benefits, such as surface tension reduction, foam control, and viscosity stabilization. The hydrophobic nature of Surfadol 541 surfactant typically results in significantly reduced water sensitivity compared to either conventional ethoxylated or anionic surfactants.

Due to its multifunctional properties, Surfadol 541 surfactant can be used in many water-based applications such as coatings, paints, adhesives, inks, pigment manufacture and dispersion, cements, metalworking lubricants, agricultural chemicals, and dye processing.

Easy-to-handle liquid preparations of Surfadol 541 are also available.

Special properties

- Quick migration, leading to low dynamic surface tension

- Ability to wet contaminated substrates

- Non-micelle forming

- Thermal and chemical stability over a broad range of conditions

- Prevents surface defect problems such as fisheyes, crawling, and cratering on low-energy substrates

- Reduces microfoam in spray-applied systems

- Improves pigment grind efficiency

- Reduces water sensitivity

- Defoams, deairentrains, and improves flow

- Enhances leaf and soil penetration while improving bloom and stability in agricultural chemicals

- Lubricates, wets, and prevents smut formation while eliminating hot spots in metalworking fluids

- Silicone-free, APEO free, non-toxic

Examples of application

- Water-based printing inks

- Water-based adhesives

- Dye processing

- Fountain solutions

- Waterborne coatings

- Metalworking fluids

- Overprint vanishes

- Agricultural chemicals

- Concrete and drymix mortars

Processing instructions

- Mix well when use.

- Added and mixed after other surfactants.

- Pigments, fillers or other solid should be added after Surfadol 541 surfactant has been evenly mixed.

Typical properties

| Active matter | 2,4,7,9-Tetramethyldec-5-yne-4,7-diol, CAS#126-86-3 |

| Active matter content | 100% |

| Dynamic surface tension (0. 1%wt. , 6 b /s) | 36 dynes/cm |

| Density at 25°C, g/cm 3 | 0.89 |

| Solubility in water | slightly soluble |

| Boiling point | 262°C |

| Melting point | 54-55°C |

| Suggested use level | 0.1% – 1.5% of total formulation weight |

Specifications

| Test Item | Standard |

| Appearance | White waxy solid |

| APHA Color (Pt-Co) | ≤350 |

| TMDD purity (GC) | ≥98.00% |

| Water Content | ≤1.50% |

Package and storage

The standard package for this material is 180kg galvanized iron drums, 4 drums/pallet.

The product is also available in 20kg pails, 18 pails/pallet.

Keep containers tightly closed in a dry, cool, and well-ventilated place. Product is freeze-thaw stable. Container should be heated to 60-70°C to completely melt product; mix thoroughly before use.

The shelf life for this product is 48 months from the date of manufacture.

For more information, please send email to: sales@acmetech.cn.